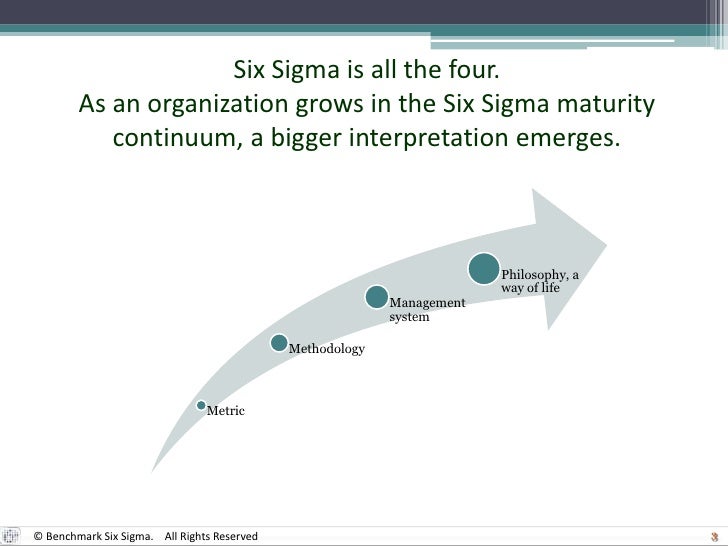

Six Sigma Is A Metric System

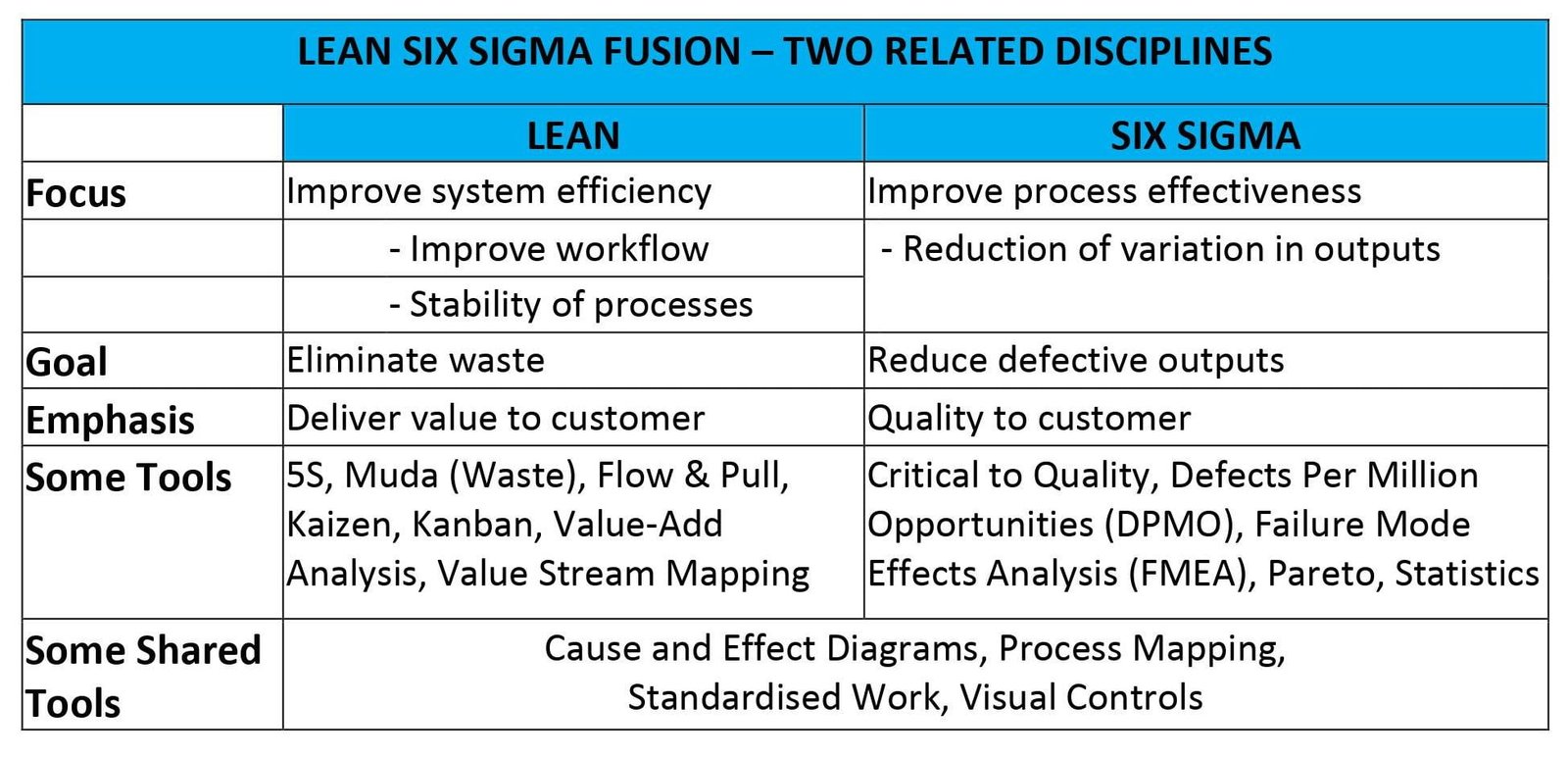

Six sigma is a metric system. Try Kanbanize for free. Lean Six Sigma projects essentially tend to reduce this variation from the processes to make them better. 1 Production Kanban - this type of system contains cards that give the approval to produce process manufacture or assemble based on the need of the next operation since there was consumption that needs to be replenished.

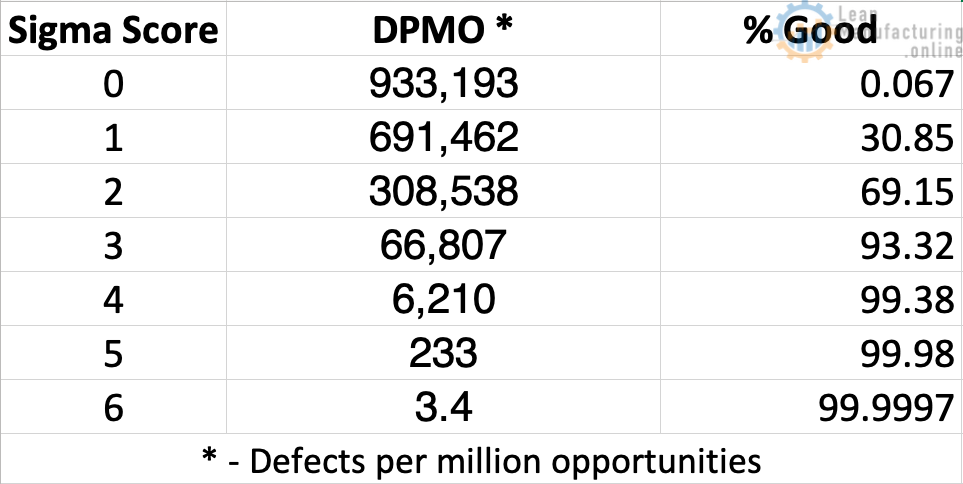

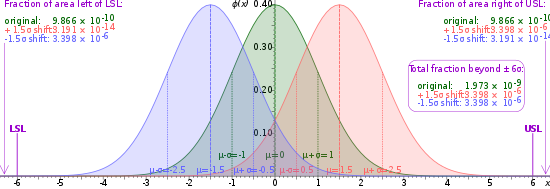

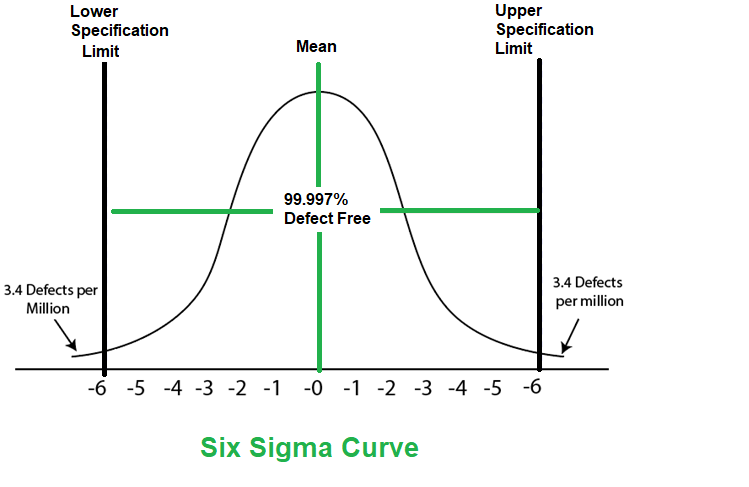

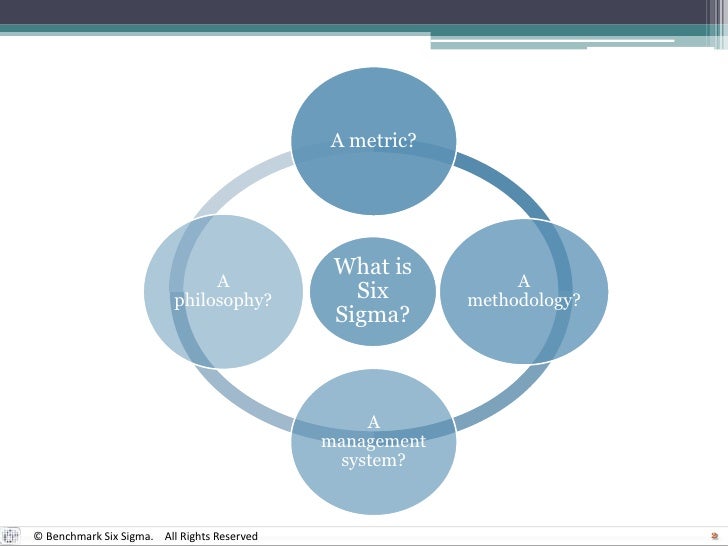

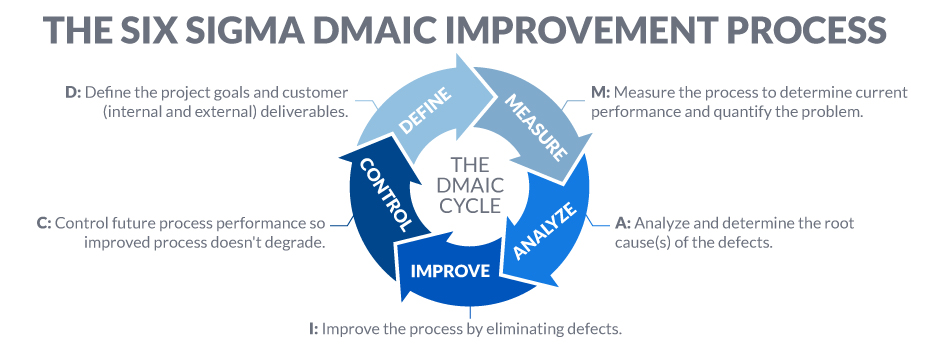

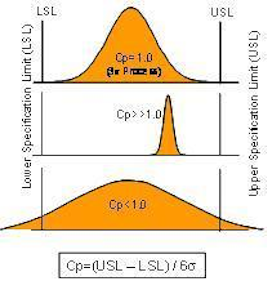

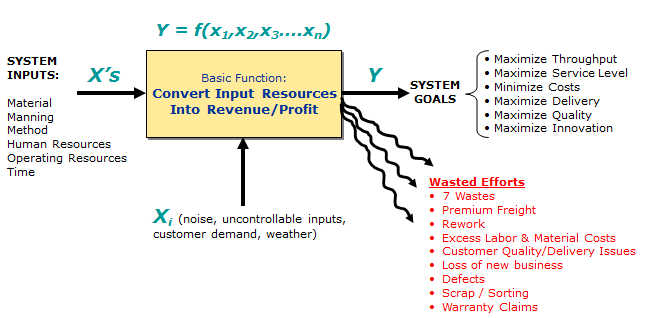

The concept behind this approach is to reduce the variation in processes. The six sigma methodologies aim to make the system more sophisticated in such a way that the process will not produce more than 34 defects per million opportunities. What is Six Sigma.

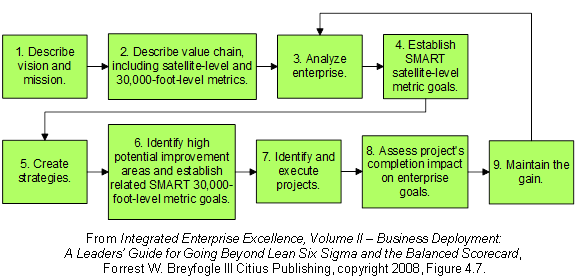

Six Sigma Calculators Statistics Tables and Six Sigma Templates to make your job easier as a Six Sigma Project Manager. Michael George describes the basic elements of successful deployment including insights from corporate leaders who have already walked the talk to accelerate your own journey. The final phase of Lean Six Sigma is the Control phase.

Lean Six Sigma for Services reveals how to bring the miracle of Lean Six Sigma improvement out of manufacturing and into service functions. The top the middle and the bottom. Measure is the second phase of DMAIC.

During the study you record the thickness of the glass in three places. Action Plan A series of planned activities with established accountabilities and delivery dates which when complete will result in the accomplishment of an objective. A six sigma process is one in which 9999966 of all opportunities to produce some feature of a part are statistically expected to be free of defects.

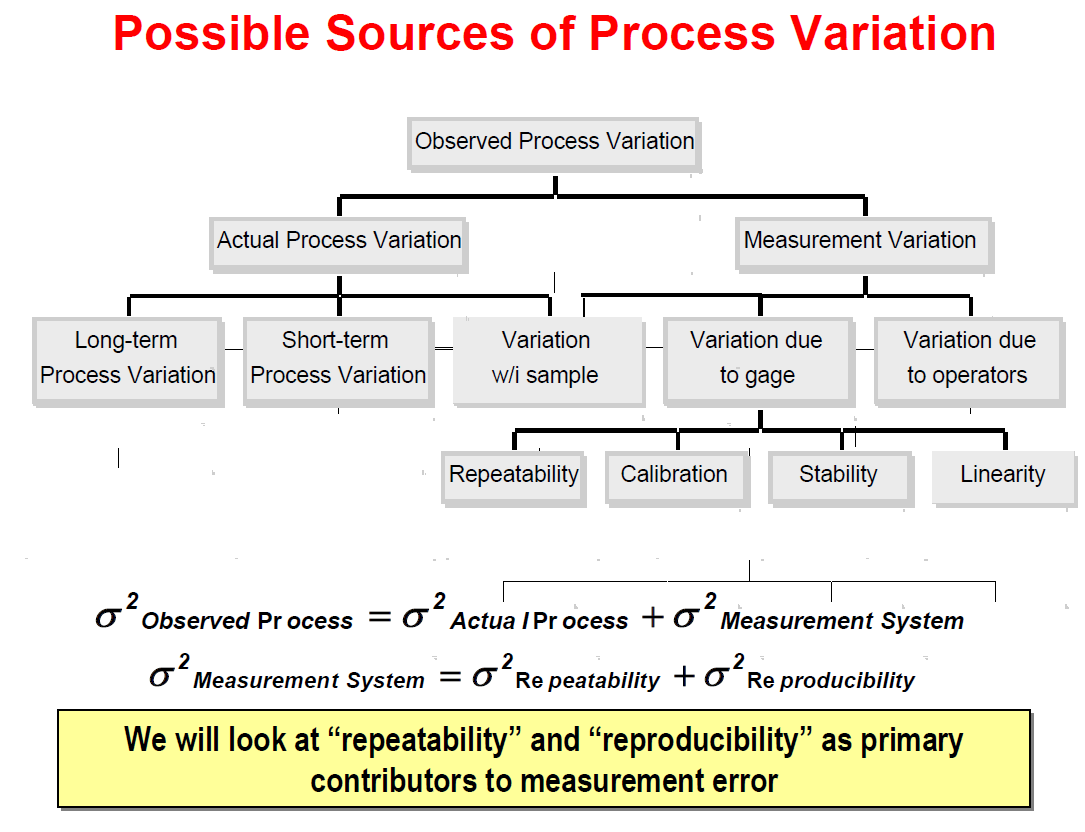

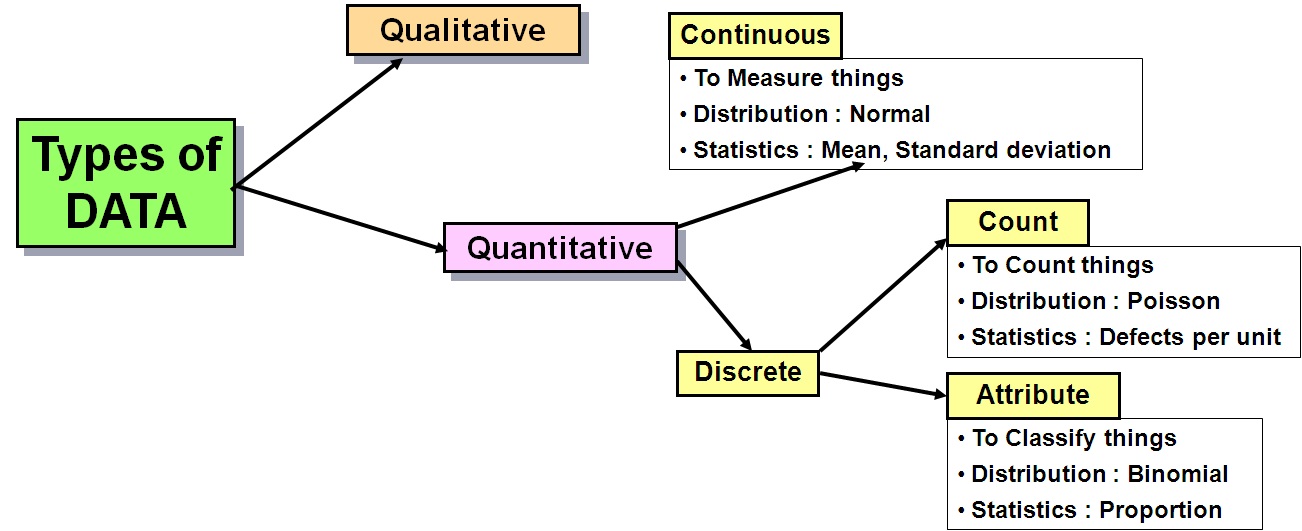

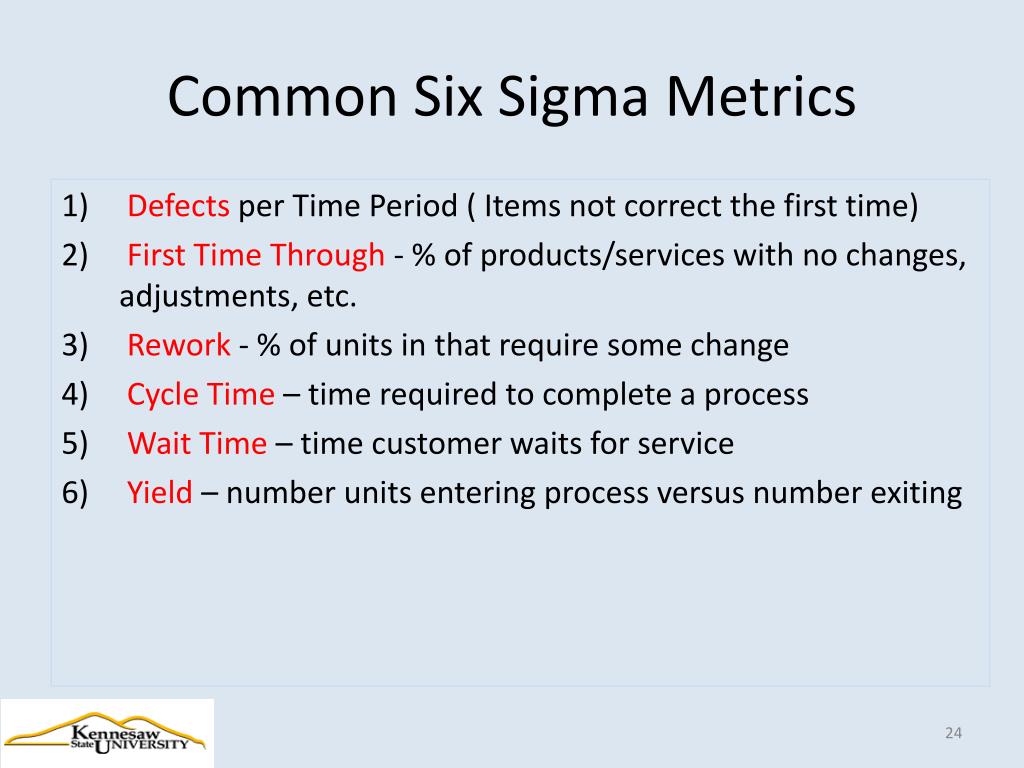

Popular Tags Accuracy BB Project Change Management Continuous COPIS Data type Discrete Distributions Gage RR measurement system analysis Measurement System Variation measures metric movement project MSA Non Normal Data Precision Process Process. We will look at most relevant measures from Lean Sigma perspective. Full PDF Package Download Full PDF Package.

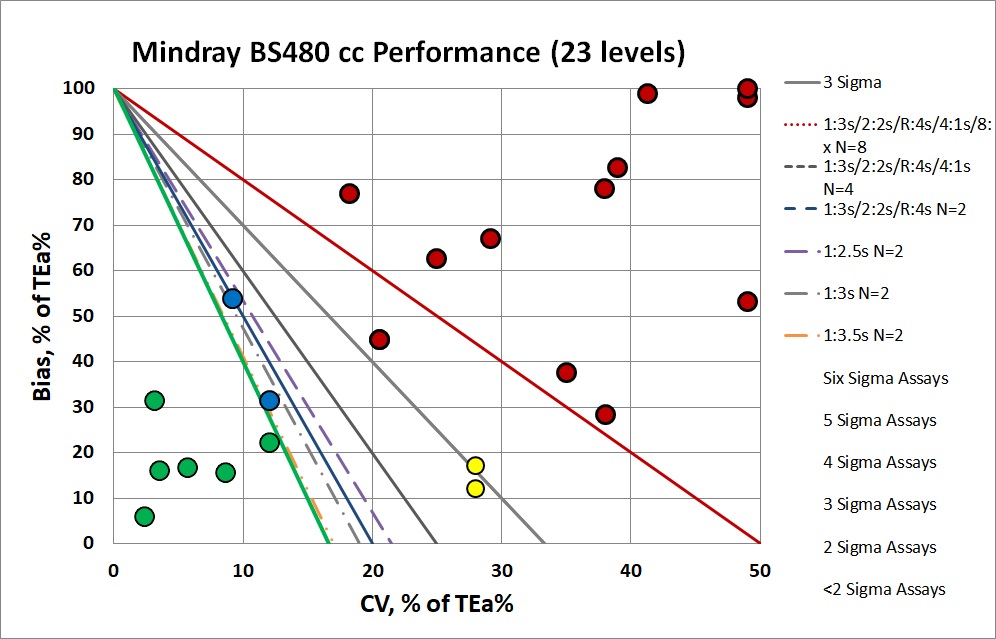

Six Sigma Risk Analysis CLIA Final Rules. Tools such as the Sigma-metric.

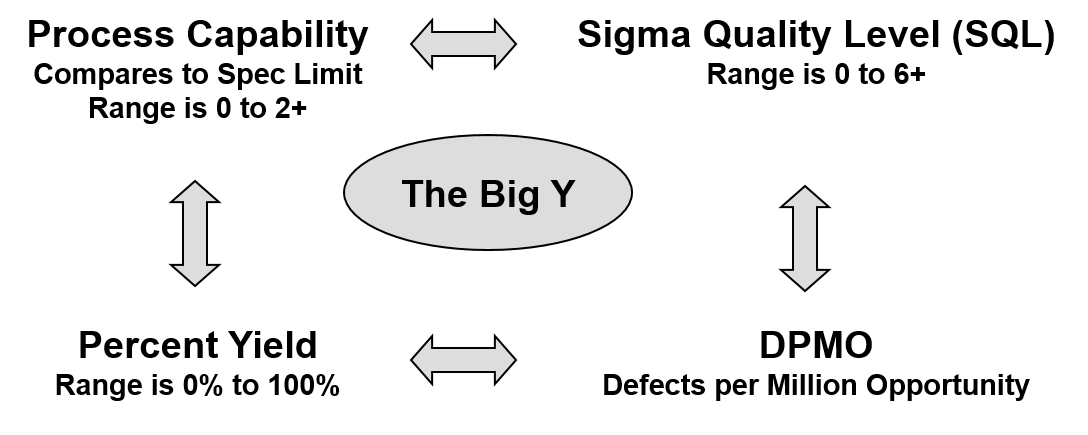

Six Sigma is a measurement-based strategy for process improvement.

The Kappa Statistic is the main metric used to measure how good or bad an attribute measurement system is. Six Sigma is a measurement-based strategy for process improvement. Even with expert use of the tools described in this book problems can arise for teams as they implement and maintain solutions. The concept behind this approach is to reduce the variation in processes. It shows how well versed you are in efficient operations management control functions and gives out a sign of having good analytical skills. For example Joes Burgers would use DPMO to figure out how successful their current serving process is and how it compares to other serving processes they might have tried. Changes in test system performance environmental conditions and variance of operation performance. The final phase of Lean Six Sigma is the Control phase. Solution includes a control system to help it stick Lean Six Sigma does not end with identifying the problem or even with implementing a solution.

The Kappa Statistic is the main metric used to measure how good or bad an attribute measurement system is. What is Six Sigma. Process Cycle Efficiency is a metric used to prioritize improvement opportunities and is computed by dividing the value-added time of process with its total lead time. We will look at most relevant measures from Lean Sigma perspective. The final phase of Lean Six Sigma is the Control phase. In Summary The Lean Six Sigma approach represents a business metric that delivers measurable results and a way to control and sustain those results. Try Kanbanize for free.

Post a Comment for "Six Sigma Is A Metric System"